The Computer on Wheels: What ADAS Calibration Is and What It Means for Your Shop

February 16th, 2026

5 min read

By Jim Jarvie

You’ve finished the structural repair. The paint is flawless, the panels are perfectly aligned, and to the naked eye, the car looks brand new. But beneath the surface, the vehicle’s "brain" is confused. A camera was unplugged during the teardown, or a radar sensor was moved by a fraction of a millimeter. On the dashboard, there are no warning lights. To many shops, this vehicle looks ready for delivery. But in the modern repair landscape, "it looks fine" is the most dangerous phrase you can use.

If you feel overwhelmed by the rapid shift from traditional bodywork to high-tech sensor alignment, you aren’t alone. Many shop owners tell us they feel like they’re being forced into a digital world they didn't sign up for. We have lived the ADAS learning curve for over 7 years. We don't just sell tools; we perform these calibrations every day and have seen how these "computers on wheels" behave in real-world scenarios that manuals often miss. We understand the pressure to turn cars quickly, but we also know that a repair isn't finished until the safety systems are validated.

By exploring the "what" behind calibration in this article, you’ll gain the clarity needed to protect your customers and turn ADAS from a technical headache into a high-ROI, revenue-producing engine for your business.

ADAS is like the "Eyes and Ears" of the Vehicle

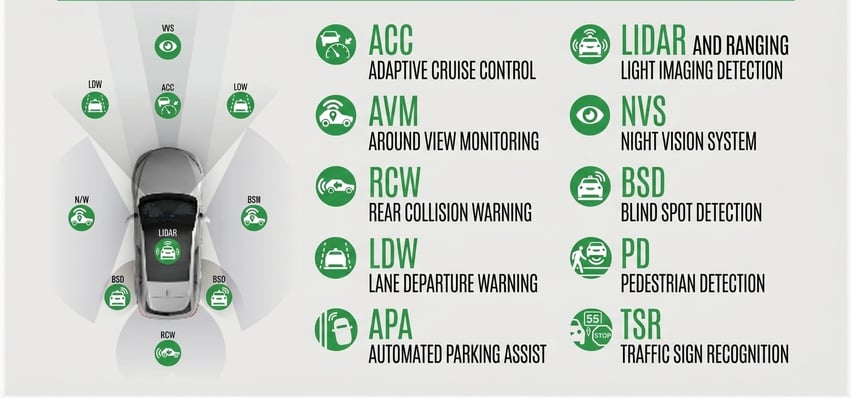

Advanced Driver Assistance Systems (ADAS) are a suite of sensors, including cameras, radar, ultrasonic sensors, and in some cases lidar, that act as the vehicle’s eyes and ears. They handle everything from automatic emergency braking to vehicle self parking.

Calibration is the process of physically and digitally "re-pointing" these sensors so they see the world accurately. As noted in BodyShop Business, ADAS Calibrations: Understanding the When-Why-How, these sensors interpret the environment based on complex geometry. If a camera is misaligned by even a tiny fraction, it can miscalculate the distance to a lead vehicle by several feet. Calibration ensures that the digital world the car "sees" matches the physical road it’s driving on.

Understanding the Individual ADAS Systems

While ADAS is often discussed as a single system, in practice it is a collection of individual components—each with a specific role, location, and calibration requirement.

By looking at the systems shown below, you can see how ADAS is presented as a set of safety and convenience features the driver experiences during everyday operation.

The following highlights eight ADAS systems you will experience when calibrating vehicles after collision, glass, or structural repairs.

- Forward Radar controls Adaptive Cruise Control (ACC) and Automatic Emergency Braking (AEB). This sensor relies on precise vertical and horizontal aim; even slight misalignment can cause late braking, unnecessary braking, or reduced detection range without triggering a fault code.

- Forward-Facing Cameras manage systems like Lane Keep Assist (LKA) and Traffic Sign Recognition (TSR). Because these cameras interpret lane markings and road signs based on exact height and angle, windshield replacement, suspension work, or alignment changes alone can require recalibration.

- Blind Spot Monitoring uses rear-mounted radar sensors to detect vehicles in adjacent lanes. After bumper or quarter panel repairs, these sensors must be revalidated to ensure consistent detection zones and reliable alerts.

- Rear View / Backup Cameras provide visual assistance while reversing and often calculate projected path lines. If camera position shifts during repair, distance perception and trajectory guidance can be inaccurate even though the image appears normal.

- Surround View (360° Camera) Systems rely on multiple cameras—typically mounted in mirrors and bumpers—to create a stitched bird’s-eye image. A single misaligned camera affects the accuracy of the entire composite view.

- Ultrasonic Parking Sensors detect nearby objects at low speeds using short-range signals. Bumper removal or replacement can alter sensor orientation, reducing accuracy or creating inconsistent alerts.

- Night Vision Systems, often mounted in the grille and operating with infrared sensors, detect heat signatures beyond headlight range. Misalignment can shorten detection distance or create blind zones the driver never sees.

- Adaptive Headlights use sensor input to manage high-beam assist and directional lighting through turns. Incorrect reference points can reduce visibility exactly when drivers rely on these systems most.

ADAS Systems Don’t Always Trigger Lights or Codes

Once you see how broad and interconnected ADAS systems are, it becomes easier to understand why they do not always trigger diagnostic trouble codes or warning lights. These systems rely on precise physical reference points that can shift or be impacted from collisions and/or repairs, even when no electrical or communication fault exists.

Because ADAS functionality depends on exact sensor position, height, and angle, relatively small physical changes can affect system performance without producing an alert. The absence of a warning light does not mean the system has not been affected, only that it is still operating despite those changes. Once you understand the safety implications, the business opportunity becomes clearer.

How to Flip ADAS Calibration From Expense to Revenue

While safety is the primary driver, the operational benefits of bringing calibration in house are transformative for a shop’s bottom line. For years, some shops have viewed calibration as a necessary evil, a sublet expense that adds days to cycle time and complicates the workflow.

It’s time to flip that script. Bringing calibration in-house turns a sublet cost into a primary revenue stream.

- High ROI and Profit Retention: Instead of sending $500 to a dealership or a mobile tech, that revenue stays in your shop. With the right equipment and training, most shops see a full return on investment much faster than they expect.

- Total Workflow Control: When you control the calibration, you control the delivery date. You no longer have to wait on a third-party schedule. This reduces cycle time, which makes both your customers and the insurance carriers happier.

- Leveraging Your Space: By designating a portion of your shop for calibration, you are maximizing the value of your square footage. You are evolving from a "hammer and dolly" shop into a high-tech center of excellence.

In a feature by FenderBender, The business of ADAS, industry experts highlight that calibration is now a standard of repair. Shops that master this "win-win" scenario improve their reputation and their profitability simultaneously.

Static vs. Dynamic: Two Pillars of Accurate Calibration

To realize these profits, you must understand the two-step process required for a complete repair:

- Static Calibration: Performed inside the shop with specific targets and laser-leveling. This establishes the vehicle’s spatial reference while stationary.

- Dynamic Calibration: The "on-road" learning process where the vehicle is driven under specified conditions so the sensors can track real-world objects for self-calibrations.

Some vehicles require both. A static calibration sets the baseline, and the dynamic test drive fine tunes the calibration.

Avoiding ADAS Calibration Liability Exposure

Liability must be addressed directly. If a vehicle leaves your shop and an automatic braking system later fails because a calibration was skipped or performed incorrectly, many questions will follow. One of the most important is: Where is the documentation?

Proper ADAS work is about building a defensible paper trail of safety. This starts with a pre-scan, continues through the physical calibration, and concludes with a final post-scan after the dynamic drive. This isn’t “extra work.” It’s how you prove a safe vehicle was returned to the road.

A New Standard of Repair

At this point, ADAS calibration should feel less like a mystery and more like a potential practical extension of the work your shop already does well. You’ve gained a clearer understanding of the components that make up modern ADAS, how tightly interconnected these systems are across vehicle manufacturers, and why accuracy depends on precise physical setup and calibration.

With the average age of vehicles on the road now around 12.5 years, collision repair increasingly involves a wide mix of older platforms and newer, technology-heavy systems. As ADAS continues to expand and evolve, collision centers will need to thoughtfully evaluate whether bringing calibration capabilities in-house makes sense in order to gain control over workflows, improve customer satisfaction, return vehicles to OEM safety specifications, and develop a new potential revenue stream.

For many shops, the next step is simply getting clarity. What would in-house calibration look like in your workflow? What volume makes sense? How does the investment pay back over time? Tools like our ROI Calculator exist for this exact reason: to let you model real-world scenarios and see how quickly calibration can move from cost center to revenue driver.

If you want to go deeper, a short strategy conversation can help connect the dots. Talking through your shop layout, current volume, and goals often turns abstract ideas into a clear, actionable plan.