Static vs. Dynamic ADAS Calibration: Understanding the Difference

February 18th, 2026

4 min read

By Jim Jarvie

ADAS calibration is no longer optional. After many common collision, glass, and structural repairs, calibration is required to restore advanced safety systems to proper operation. Yet one of the most common—and costly—points of confusion for repair facilities is understanding that there are two distinct types of ADAS calibration—static and dynamic—and that they are not interchangeable.

Calibration is not a single task completed by connecting a scan tool and waiting for a success message. It is a procedure-driven process defined by the OEM and highly sensitive to environment, setup, and execution. Some systems must be calibrated with the vehicle stationary using precise reference targets. Others must be calibrated while driving under specific real-world conditions. In some cases, OEMs require both methods to be performed in sequence.

Shops often struggle here because static and dynamic calibrations solve different technical problems, yet they are frequently discussed as if they serve the same purpose. That misunderstanding leads to missed steps, failed calibrations, delivery delays, and disputes over whether a repair was completed correctly.

If the differences between static and dynamic ADAS calibration have ever felt unclear, you’re not alone. At Applied Automotive Technology Inc., we draw on years of hands-on ADAS calibration experience to help make sense of static versus dynamic calibrations—how each works, when OEMs require one or the other (or both), and why it matters for returning vehicles to the road safely, consistently, and with confidence.

What Static ADAS Calibration Is and Why OEMs Require It

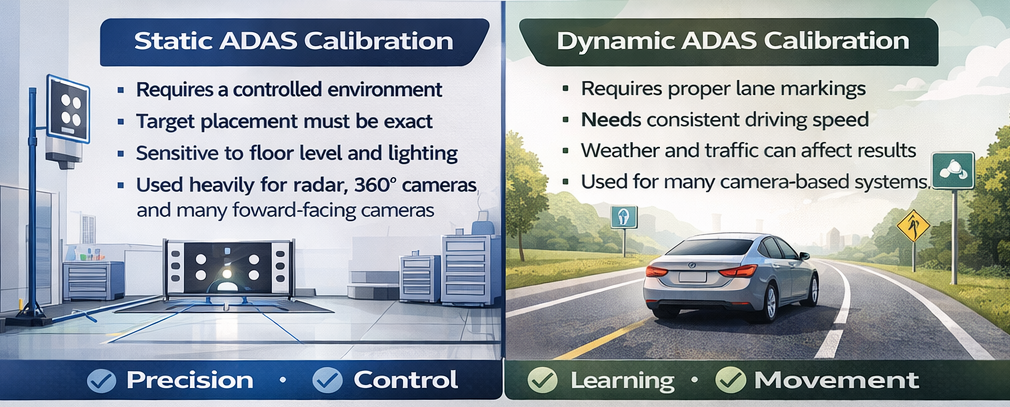

Static ADAS calibration is performed with the vehicle stationary in a controlled environment. Physical targets are positioned at precise distances and heights relative to the vehicle, and a scan tool commands the system into calibration mode so the sensors can learn their spatial reference.

Because static calibration relies on known reference points, setup accuracy is critical. Floor levelness, vehicle ride height, centerline alignment, target placement, lighting, and background conditions all matter. Small deviations can cause calibration failure or inaccurate results.

OEMs commonly require static calibration for forward-facing cameras, radar sensors, adaptive cruise control, and lane-keeping systems where precise physical orientation is essential. While modern equipment has reduced manual setup effort, static calibration remains dependent on a properly prepared environment.

What Dynamic ADAS Calibration Is and How Driving Conditions Affect Results

Dynamic ADAS calibration is performed while the vehicle is driven with a scan tool connected. Instead of using physical targets, sensors and cameras observe real-world inputs such as lane markings, road edges, steering input, and vehicle speed.

During the drive, the system determines whether sensors can electronically adjust themselves or whether additional steps are required. The scan tool provides on-screen instructions that must be followed until calibration completes.

Unlike static calibration, dynamic calibration introduces variables the shop cannot fully control. Traffic, weather, road conditions, visibility of lane markings, and route availability all affect success. As a result, dynamic calibrations can take unpredictable amounts of time and may fail even when procedures are followed correctly.

How Static and Dynamic Calibration Differ in Real Shop Operations

Static and dynamic calibration solve different engineering problems. Static calibration teaches the system using known reference points in a controlled environment. Dynamic calibration validates or adjusts system behavior using real-world driving conditions.

From an operational standpoint, static calibration rewards preparation and repeatability. Once space and procedures are dialed in, results are consistent. Dynamic calibration requires flexibility, additional planning, and accommodation for external factors that can disrupt schedules.

Neither method is interchangeable. Each exists because the OEM determined it was necessary for system accuracy.

Why OEMs Specify Static Calibration, Dynamic Calibration, or Both

The calibration method is not a shop decision. OEMs define required procedures based on the vehicle, the ADAS feature involved, and the type of repair performed.

I-CAR’s article Considerations for Dynamic Calibration explains that dynamic calibration is becoming more common as ADAS technology evolves, but it also introduces practical considerations. Dynamic calibration involves driving the vehicle while connected to a scan tool so sensors can observe real-world surroundings. When the system cannot see what it expects, it communicates through the scan tool, prompting specific driving instructions.

I-CAR emphasizes that dynamic calibration should never be treated as a solo task. A second technician is often required to monitor scan-tool instructions. Access to OEM service information is critical, as speed, fuel level, and road conditions vary by vehicle. Internet connectivity may also be required during the drive.

Time variability is another key consideration. Even identical vehicles can require different calibration durations depending on traffic and weather. These factors explain why OEMs sometimes require static calibration first, followed by dynamic validation.

The Most Common Mistakes Shops Make When Choosing a Calibration Method

Even experienced shops encounter issues when calibration requirements are misunderstood:

- Assuming one successful calibration covers everything. A completed static calibration does not mean a dynamic calibration is unnecessary.

- Overlooking static setup requirements. Uneven floors, improper ride height, or incorrect target placement can invalidate results.

- Underestimating dynamic variability. Weather, traffic, and road availability frequently cause late-stage failures.

- Treating calibration as a scan-tool task instead of a workflow. Calibration is a sequence, not a button press.

Why Performing the Wrong Calibration Method Creates Risk

Incorrect or incomplete calibration has consequences beyond a failed scan:

- Safety risk: ADAS features may not function as intended.

- Liability exposure: Incomplete documentation weakens defensibility.

- Payment disputes: Insurers increasingly scrutinize calibration procedures.

- Cycle-time disruption: Failed calibrations delay delivery and scheduling.

Body Shop Business reinforces these risks in its article Static and Dynamic Vehicle Calibrations: Are You Following the Process?, noting that missed steps and poor documentation often lead to rework and disputes.

How Understanding Calibration Differences Improves Consistency, Workflow, and Outcomes

Shops that succeed with ADAS calibration approach it systematically. They plan space so static calibrations can be performed accurately and account for staffing, time variability, and road access when dynamic calibration is required. Technicians understand not only how to perform calibrations, but why each step matters.

When calibration is treated as a defined workflow rather than an exception, results become repeatable. Documentation improves, rework decreases, and scheduling becomes more predictable.

What a Clear Understanding of ADAS Calibration Means for Your Shop

By now, you should have a clear understanding of how static and dynamic calibrations differ, why OEMs require one or both, and how environment and process directly affect outcomes.

Static and dynamic ADAS calibration are not competing approaches. They are complementary processes designed to restore advanced safety systems after repair. When these differences are understood and applied correctly, calibration stops being a source of uncertainty.

If this article helped clarify the difference for you, the next question might be whether bringing calibration in-house makes sense for your shop, your space, and your volume.

Talk to an ADAS Expert. We’ll walk through the process with you step by step, explain what’s required for the vehicles you typically repair, and answer your questions in a straightforward, no-pressure conversation—so you can move forward with confidence.