No DTC Codes? Busting the Myth That Calibration Isn’t Required

February 9th, 2026

4 min read

By Jim Jarvie

One of the most common assumptions in collision repair is that if a post-repair scan shows no diagnostic trouble codes (DTCs) and no warning lights, ADAS calibration isn’t necessary. That belief feels logical, but it’s wrong, and it can leave vehicles out of specification, expose shops to liability, and compromise safety.

ADAS calibration requirements are not determined by fault detection. They are determined by OEM repair procedures and the work performed on the vehicle.

Understanding the difference between system failure and system accuracy is critical to making the right call after a collision.

In this article, we’ll explain why a clean scan does not confirm ADAS accuracy, what DTCs actually tell you and what they don’t, and how to make calibration decisions that align with OEM standards, not assumptions.

Why the “No Codes” Myth Persists

For decades, warning lights and fault codes were reliable indicators of problems. If something failed, the system provided an indication. If there was no code, the system was assumed to be functioning correctly.

ADAS systems changed that model.

Modern cameras, radar units, and sensors are designed to operate within tolerance ranges. They can remain functional even when they are slightly misaligned, sometimes enough to affect real-world performance but not enough to trigger a fault. As a result, the absence of a code is often misinterpreted as proof that calibration is unnecessary.

In reality, the system can be operating and still be inaccurate.

What DTCs Actually Tell You (and What They Don’t)

Diagnostic trouble codes exist to identify failures, not to verify precision.

A DTC indicates that a control module has detected an electrical issue, communication error, or component malfunction. What it does not do is confirm that sensors are properly aimed, aligned, or calibrated after repairs.

ADAS calibration is about restoring accuracy after physical changes to the vehicle, not about fixing broken electronics.

This distinction is well documented. As explained by REVV in DTCs and ADAS Calibrations: What You Need to Know, calibration requirements are driven by the repairs performed and OEM specifications, not by whether a fault code appears.

ADAS Systems Can Be Inaccurate Without Setting a Code

Many ADAS systems have no way of knowing they are out of position unless the misalignment is severe.

The vehicle does not recognize that it has been in a collision, and if components were not electrically damaged, there may be no internal trigger to alert the system that accuracy has changed. As a result, sensors can continue operating normally while providing data that is no longer precisely aligned to the vehicle’s geometry.

Calibration exists to verify accuracy, not to respond to a failure a vehicle can detect on its own.

Calibration Is Verification, Not Repair

One of the reasons the “no DTCs” myth persists is because calibration is often misunderstood as a repair step, rather than a verification step.

When a component fails electrically, the vehicle can detect the problem and report it through a fault code. Calibration serves a different purpose. It verifies that sensors are correctly positioned and referenced after repairs that may have altered the vehicle’s geometry or mounting points.

In many cases, nothing is broken. A camera, radar unit, or sensor may be fully functional, communicating normally, and operating within its expected electrical parameters. What calibration confirms is whether that component is still interpreting the world accurately based on its physical position on the vehicle.

OEMs require calibration not because they expect failure, but because they recognize that accuracy cannot always be self-diagnosed by the vehicle. In other words, calibration is the external check that confirms systems are performing as designed after repair work is completed.

Understanding calibration as verification, not troubleshooting, helps clarify why scan results alone are not sufficient.

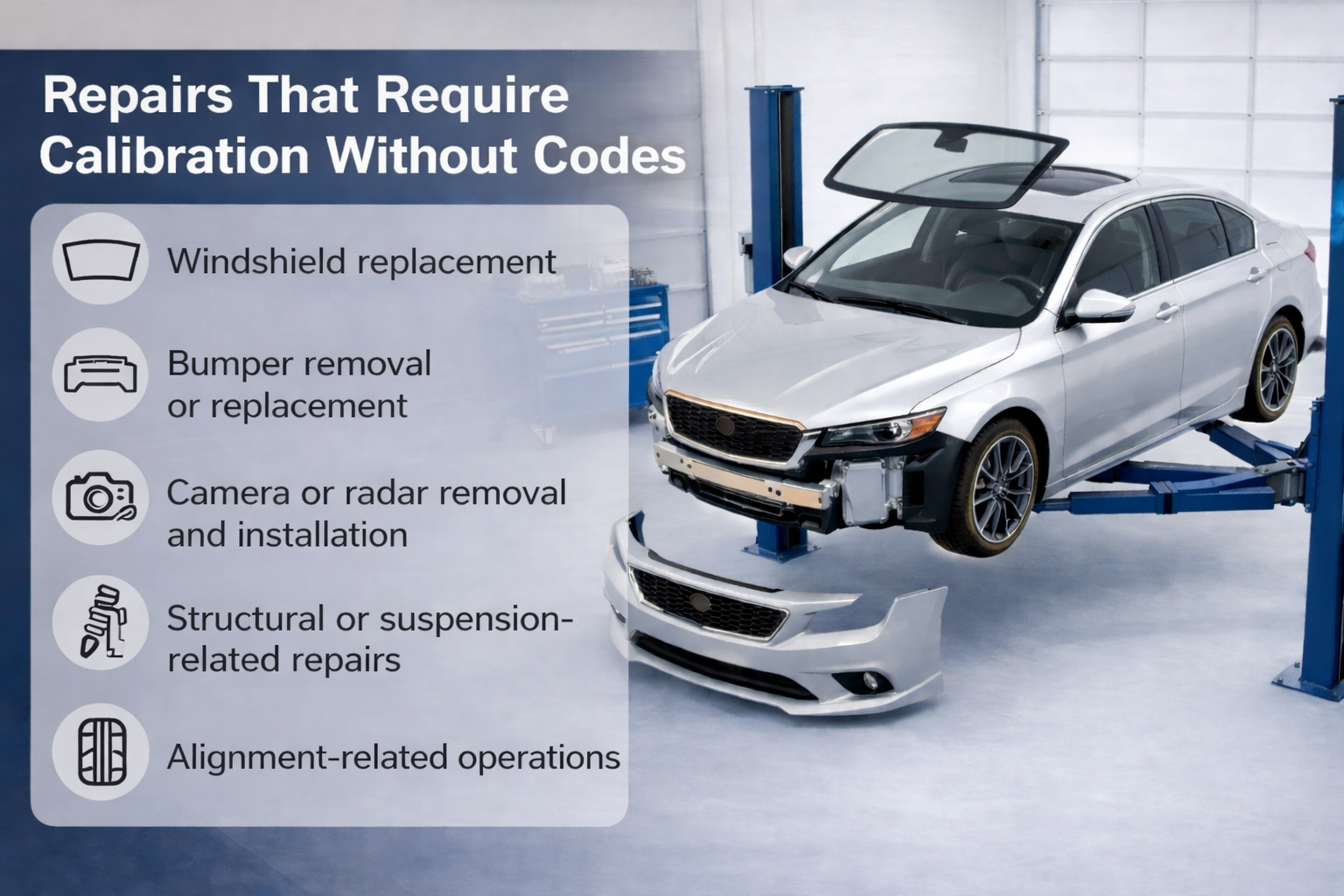

Repairs Often Require Calibration Even With No Codes

OEMs base calibration requirements on repair events, not symptoms. Many common collision repairs can affect sensor positioning without triggering a warning light.

If an OEM procedure specifies calibration after one of these operations, it is required regardless of scan results.

"It Drives Fine" Is Not Proof

Another common misconception is that drivability confirms ADAS accuracy.

A vehicle can drive normally and still have misaligned ADAS systems. Many safety features only activate under specific conditions, such as emergency braking, adaptive cruise events, or lane departure scenarios. If those conditions aren’t encountered, issues may never surface during a test drive.

That’s why OEMs tie calibration requirements to the repair operations performed—not to post-repair drivability impressions.

The Risk of Relying on No Codes

Skipping OEM-required calibration because no codes are present creates unnecessary risk.

From a liability perspective, the key question is not whether a warning light was on; it’s whether the vehicle was restored according to manufacturer specifications. If calibration was required and not performed, the absence of a DTC offers no protection. Only OEM documentation provides that protection.

How Well-Run Shops Verify Calibration Requirements

Well-run shops do not guess when it comes to ADAS calibration. They verify. A sound decision process starts with the repair plan, considers which components were removed or disturbed, and references OEM repair procedures to determine whether calibration is required. Scan results play a role, but they are not the deciding factor.

Tools that analyze repair operations and flag OEM-required calibrations can support this workflow by helping ensure required steps are not missed and by strengthening documentation. These tools reinforce OEM guidance. They do not replace it.

Setting the Record Straight

The belief that “no DTCs means no calibration” persists because it feels intuitive. But ADAS systems don’t operate on intuition. They operate on physics, geometry, and precision.

Calibration is not about responding to failure. It’s about verifying accuracy after repairs that can affect sensor alignment. That determination comes from OEM requirements, not warning lights.

Now you know why a clean scan does not confirm ADAS accuracy, and why relying on DTCs alone creates risk. When calibration decisions are based on OEM procedures and supported by proper documentation, accuracy is verified, liability is reduced, and vehicles are returned to service as manufacturers intended.

If you’d like help putting this into practice, our team is here to walk through OEM requirements, documentation, and what a dependable ADAS calibration workflow could look like for your shop.