Search for topics or resources

Enter your search below and hit enter or click the search icon.

January 29th, 2026

4 min read

By Jim Jarvie

Mobile ADAS calibration plays an important role in today’s collision repair landscape. Many shops rely on mobile providers when space is limited or in-house calibration isn’t practical, even though mobile work can still introduce workflow considerations that need to be managed.

Because mobile calibrations are performed in changing environments, shops must be mindful of additional considerations to ensure accuracy, OEM compliance, and safe outcomes for customers.

Our team has spent more than seven years performing ADAS calibrations across a wide range of makes and models, working closely with body shops, collision centers, and mobile calibration providers. We’ve seen mobile calibration done well, and we’ve also seen how small details can get missed when environments change.

This article focuses on what "done correctly" actually looks like in practice:

ADAS calibration is precise work. OEM procedures exist because even minor deviations in setup or environment can affect how a system performs once the vehicle is back on the road.

A calibration that looks successful on a scan tool does not always guarantee proper real-world performance.

Mobile calibration can be a smart solution for many shops, but it still must meet the same technical requirements as in-house calibration. The difference is that mobile work introduces more variability.

From shop to shop, calibrators encounter different floor conditions, lighting situations, space constraints, and surrounding objects. When those variables aren’t controlled or properly compensated for, accuracy becomes harder to guarantee.

ADAS calibration is not forgiving. Small setup errors can multiply once a system begins “seeing” down the road. A calibration can pass while still being inaccurate, affecting how a safety system performs in real driving conditions.

According to Body Shop Business, even minor environmental or setup deviations during mobile calibration can result in systems that appear calibrated but do not perform as intended. This is why OEMs specify exact target distances, heights, lighting conditions, and floor-level tolerances.

Proper mobile calibration requires more than bringing the right tools to the vehicle. The environment must meet OEM expectations. This includes level surfaces, or equipment that compensates for uneven floors, along with adequate space for OEM-specified target distances, controlled lighting, and minimal nearby metal surfaces that could interfere with radar-based systems.

Some environmental factors may seem minor in a busy shop. Unmanaged sunlight, visual clutter, reflective surfaces, or airborne dust can influence how cameras and radar sensors interpret targets.

Well-prepared mobile calibration providers recognize these risks. Many bring neutral backdrops, portable lighting, and calibrated measuring tools to help manage environmental variables and ensure consistent setups from shop to shop.

At a minimum, shops should expect the mobile calibration environment to address:

In some mobile calibration setups, equipment choice can help manage environmental challenges such as uneven floors. ADAS calibration frames like Autel’s MaxiSYS ADAS IA700 are commonly used in mobile environments to support more consistent setups.

Every ADAS calibration should begin with the OEM procedure for the specific vehicle being calibrated. Procedures vary by manufacturer, model, system, and trim level. Because of this, targets, measurements, and setup steps are not interchangeable. In some cases, calibration equipment manufacturers also publish procedures or requirements that must be followed in alignment with OEM guidance.

A provider doing it right will reference the OEM procedure, apply any applicable calibration equipment requirements, use the correct targets for that system, and follow the specified measurements and setup process.

A proper mobile calibration workflow should consistently include:

Before calibration begins, the vehicle must be ready. Certain conditions can affect calibration accuracy and should be confirmed before the process starts.

A quality mobile calibration process should verify:

If these conditions are not met, calibration results may appear successful while still being inaccurate and should be addressed before calibration proceeds.

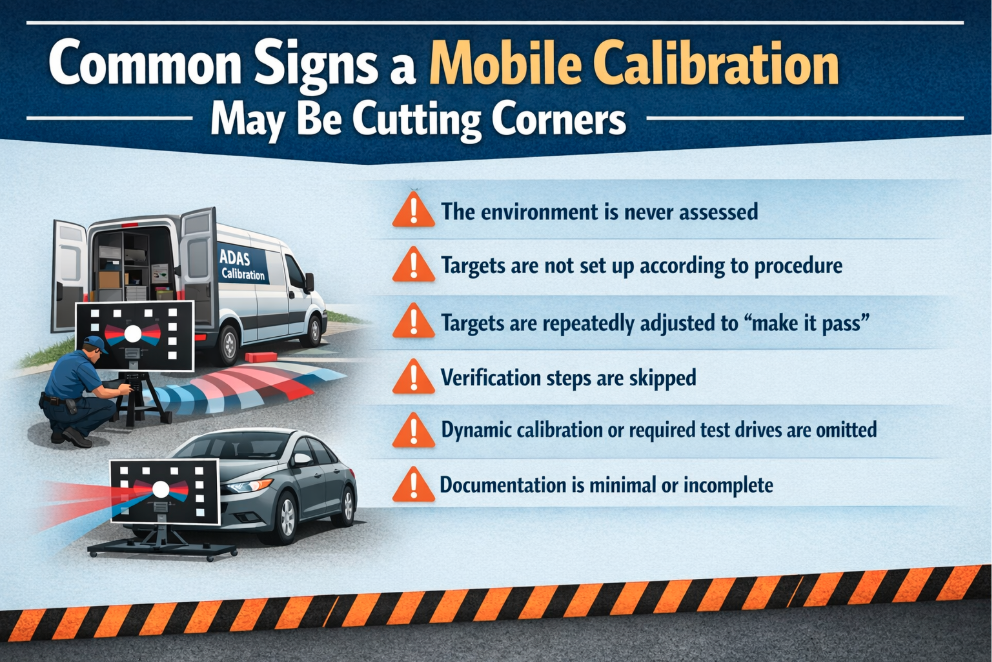

Even well-intentioned mobile calibration work can fall short when environmental conditions, setup requirements, or verification steps are overlooked. These situations often arise from time pressure, changing shop conditions, or assumptions that certain steps are “close enough.” While none of these signs automatically mean a calibration is incorrect, they should prompt a closer look and a conversation.

Shops that are comfortable asking how a calibration will be set up, verified, and documented are better positioned to achieve consistent outcomes. A few thoughtful questions at the right time can help prevent rework, protect customer safety, and reduce avoidable liability.

For additional guidance, Autel offers an ADAS Setup Reverse Lookup Guide that helps shops reference vehicle-specific calibration setup requirements before calibration begins.

Targets must be placed at precise distances, heights, and angles, following OEM or equipment specifications. Repositioning targets simply to achieve a successful result introduces risk, as a vehicle may accept a calibration even when setup is incorrect. Careful measurement and stable positioning are key indicators that the calibration is being performed correctly.

Static calibration alone does not confirm that ADAS systems function correctly on the road. Many OEM procedures include or recommend dynamic validation, meaning the vehicle is driven after calibration.

A complete workflow often includes a pre-scan and pre-drive, followed by static calibration, then a post-scan and post-drive. This confirms what changed during calibration and verifies that systems operate as intended in real driving conditions, not just on the scan tool.

There is no single “correct” amount of time for an ADAS calibration. Rushed work often means steps were skipped, while proper setup, verification, and validation take time. Strong documentation supports that process by protecting all parties involved. It shows the shop, calibration provider, and insurer that the work was performed correctly and in accordance with requirements.

Mobile ADAS calibration can be done correctly, and many providers do excellent work. But changing environments introduce variables that must be managed carefully. Shops that understand what to watch for are better positioned to ensure customer safety, meet OEM requirements, and protect themselves from avoidable liability.

If you’re evaluating mobile calibration, considering bringing ADAS calibration in-house, or deciding how to balance both approaches, we’re happy to help you think it through based on your space, volume, and workflow.

Topics: